From the Main Menu, navigate to Work Orders:

All work orders for unscheduled maintenance are viewed within Work Order Manager. This includes work orders created from service requests and newly created work orders from the facilities/maintenance department. If a work order was created from a service request, it will include all previously entered information that applies to the service request. Access each tab as described below to complete the work order.

The data here can be filtered to only show incomplete work orders. To view all work orders, complete and incomplete, click the Show All Records icon.

Service requests can be converted to work orders (as shown in the Service Request chapter). When that has happened, you can navigate here to Work Order Manager to edit and complete them. Otherwise, when a service request is not involved, navigate to the Work Order Manager -> Information tab and click the New button to create a new record.

The Work Order No. is automatically populated based on the numbering scheme defined within the Configuration -> Admin Settings -> Automatic Numbering tab. Please see the FaciliWorks Administrator Guide for more information about Admin Settings.

Asset ID: Use the pop-up list to select the asset that requires work to be done. Selecting an Asset ID will automatically populate the Asset Description field.

Task ID: By default, only the Task IDs that are associated with the selected Asset ID will be available in this pop-up list. To view all Task IDs, click the Show All button to the right of the Task ID field. Making a selection in this field automatically populates the Task Type field and the Task Description field.

Problem Code: The problem that prompted the work order can either be selected from the pop-up list or can be entered here.

Cause: In this field, select the reason for the work order (your system administrator creates this list during program setup; see Work Order Cause Entry in the FaciliWorks Administrator Guide for more information.

Action Taken: Once something has been done about the issue, indicate the action taken. Entries here can be added to the pop-up list.

The Record Created fields (time and date) are automatically populated with the current system date and time.

Technician: If a technician was assigned to this particular task within Data Administration -> Tasks, that person’s Staff ID will appear in this field. Otherwise, use the pop-up list to select a technician.

The Entered By field automatically displays the name of the user currently logged in, but can be changed by making another selection from the pop-up list.

Task Priority: Use the pop-up list to specify the importance of the task.

Task User 1 and Task User 2: These fields contain the user-defined information for each task. FaciliWorks pulls this information from Task Entry, but it can be edited here to suit this particular work order.

Comments: Any information that you enter in this field will also appear in work order history reports, work order cost reports and on the printed work order.

Required Shutdowns: If you must shut down the asset and/or the facility to perform the task, check the appropriate checkboxes under Required Shutdowns.

Emergency: If this work order is for emergency maintenance, check this checkbox.

Progress Name: This field shows the status of the work order. By default, FaciliWorks automatically updates the status of work orders when they are created or completed. The Progress Name can be manually altered by making another selection from the pop-up list. For information about editing progress names or creating new ones, please see the FaciliWorks Administrator Guide.

Progress Text: Enter comments about the status of the work order, for example, Part Number X-0011 is on backorder.

Progress Set: FaciliWorks automatically enters the date of the last change in the progress of this work order. This date can be changed manually.

Progress Change: Enter the date on which the progress of this work order is expected to change next; e.g., if you are waiting for a part, enter the date on which the shipment is expected.

Cost Center: Select the Cost Center to which the work order costs will be applied.

Budget Month: Select the month to which the work order costs will be applied. By default, the current month appears in this field.

Budget Year: Enter the year to which the work order costs will be applied. By default, the current year appears in this field.

Asset Entry: Click this button to access the original asset record for the asset specified in the work order.

Asset WO History: Click this button to display all work orders for the asset specified in the current work order. Please note that clicking this button will not show the record currently being displayed.

Component WO History: Click this button to display all work orders of the components of the selected asset. Please note that clicking this button will not show the record currently being displayed.

Preview WO: Click this button to see a print preview of the work order. From this screen, the work order can be printed or exported as a file.

Preview Compact WO: Click this button to view a summarized version of the work order. From this screen, the work order can be printed or exported as a file.

Preview Request: If the work order was created via a service request, click this button to view the service request that prompted this work order.

The following fields are to be used once the work has been performed and all information has been entered into the other tabs within the work order record.

Completed: When the task has been performed, check this checkbox. This action completes the work order, deducts parts used, charges cost centers and completes the information regarding the open work order. If there is any missing information in the component tabs such as actual hours used to perform the task, actual parts used, or checklist items not checked as well as the date that the maintenance was completed, FaciliWorks will prompt you for this information before the work order is completed. After the record is saved, you will be directed to sign the work order if the electronic signature feature is enabled.

Check the appropriate Shutdowns Performed box after the work has been performed.

Maintenance Done Date: Enter the date on which the task was completed.

Maintenance Done Meter: Enter the asset’s meter reading at the time at which the task was completed.

Downtime _____ Hours: In this field, FaciliWorks will automatically fill the hours from the task record; edit this field to reflect actual downtime for the work order.

Cost Proportion: Enter the cost of the work order in relation to the cost center budget. The value entered can be in percentage form or the actual amount.

In the Schedule tab, you can view the maintenance scheduling information auto-filled from the task record. Any of these fields can be changed prior to the completion of the work order. This information becomes part of the maintenance history for the asset.

The six fields at the top of the form are populated with information entered in the Information screen.

Rollover Meter Reading: The reading before the meter rolls back to zero.

Total Time/On Current Meter columns: Enter the Maintenance Done Meter and Meter Due values in the Total Time column. FaciliWorks enters values in the On Current Meter column based on the value entered in Rollover Meter Reading.

Meter Due: Enter the meter value at which the asset will be due for maintenance.

Next Date Due: Enter the date by which this work order must be performed. The priority of the work order and whether or not it was marked as an emergency affect the date that populates this field. The date can be manually changed.

The following fields are to be used once the work has been performed:

Maintenance Done Meter: Enter the meter value of the asset after the work order has been performed.

Maintenance Done Date: Enter the date on which the work order was performed.

Early, On Time and Late: These options refer to the time at which the work order was performed compared to the Meter Due.

Occurrence is the date on which the problem occurred that prompted the unscheduled work.

Resolution: Enter the date on which problem was corrected.

In the Labor tab, you can edit the labor information for the current work order task.

Staff ID: Use the pop-up list to select the Staff ID of the employee to whom this work order is assigned. Upon selection of the Staff ID, the Staff Name and Craft Code will be automatically populated with information from the Staff Entry record.

Estimate the number of hours this task should require and enter the numeric value in the Est Hours field. Press the Tab key on your keyboard and the Labor Cost field will be populated. This dollar amount is the product of the staff member’s hourly rate and the estimated number of hours.

When work is completed, enter the number of hours spent on the job in the Actual Hours field and press the Tab key on your keyboard; the Labor Cost field will be updated with the adjusted amount.

If the time spent on the job involves overtime, enter the number of Overtime Hours. FaciliWorks will automatically enter a value in the Regular Hours field (the difference between Actual Hours and Overtime Hours). The Labor Cost field will be updated accordingly.

If you would like to attribute a percentage of the Labor Cost dollar amount to a particular cost center, choose one from the Cost Center pop-up. The Budget Month and Budget Year fields will populate with the current month and year. These fields can be edited. In the Cost Proportion field, enter the percentage of this labor record to be attributed to the specified cost center for the specified month and year. This information is tracked and displayed within Data Administration -> Budget Entry.

Click Save and a new blank row of fields will appear, allowing you to enter another labor record.

Access the Contracts tab to enter contractor information associated with the work order. Make a selection from the Reference ID pop-up list. All related fields will auto-fill from information entered within Data Administration -> Contractors:

Enter the number of hours the job required in the Actual Time field; the Rate Cost field will be populated. The value in this field is the product of the number of Actual Hours spent and the contractor’s hourly rate.

If you would like to attribute a percentage of the Rate Cost to a particular cost center, choose one from the Cost Center pop-up. The Budget Month and Budget Year fields will populate with the current month and year. These fields can be edited. In the Cost Proportion field, enter the percentage of this contractor record to be attributed to the specified cost center for the specified month and year. This information is tracked and displayed within Data Administration -> Budget Entry.

Click Save and a new blank row of fields will appear, allowing you to enter another contractor record.

In the Parts screen, you can edit the information for the parts already selected for the current task and add new parts. As in the other selection screens, the fields are editable.

Use the Part No pop-up list to select a part number; the Description and Model fields will auto-fill with information from Part Entry. If the part is not in the database, you can enter it here to be specific to the work order; enter a Part ID and follow the prompts.

Enter the estimated quantity of parts needed for this work order in the Est. No. field; the Part Cost field will be auto-filled with the product of the Est. No. and the cost per unit entered within Part Entry.

When the work order has been completed, revisit this form to enter the Number Used. FaciliWorks automatically calculates and display the total cost in the Part Cost field.

If you would like to attribute a percentage of the Rate Cost to a particular cost center, choose one from the Cost Center pop-up. The Budget Month and Budget Year fields will populate with the current month and year. These fields can be edited. In the Cost Proportion field, enter the percentage of this contractor record to be attributed to the specified cost center for the specified month and year. This information is tracked and displayed within Data Administration -> Budget Entry.

Save the record and a new blank row of fields will appear, allowing you to enter another record. Upon saving the record, a reorder point alert may appear depending on the inventory level of the part, in which case FaciliWorks has generated a record to facilitate the creation of a work order. To view these records, navigate to Inventory -> Create Purchase Orders.

Use this window to assign tools to work orders. When you select a Tool ID from the pop-up list, FaciliWorks will automatically update the associated fields with each tool’s information.

If the tool is currently issued out, the Issued checkbox will be checked; this checkbox is not editable in this screen.

After selecting the tool, click Save and a new blank row of fields will appear, allowing you to enter another tool record.

Work Order Manager - Variables Tab

If the task associated with this work order has variable data attached to it, the Variables screen displays that variable information that you entered in the Tasks -> Variables tab. In this screen, you can edit the variable information to apply specifically to this work order.

Use the Variables pop-up list to select a variable; the related fields will auto-fill with information entered within Data Administration -> Variable Data.

Click Save and a new row of fields will appear, allowing you to enter another record.

When the work has been performed, revisit this tab to enter the Reading taken during the course of the task and click Save. If the Reading falls between the Minimum and Maximum values, FaciliWorks will check the Pass checkbox.

If the Reading does not fall between those two values, after clicking Save, you’ll be prompted to create a service request to correct the out-of-tolerance condition for this variable. If you do not want to create a service request at this time, click No to return to the Variables tab. Clicking Yes will automatically create the service request and a confirmation message will appear. If the preferences specified in Configuration involve sending an email to a person or team when a service request is created, an email confirmation message will appear.

Work Order Manager - Attachments Tab

Use this tab to attach instance-specific documents to work orders, such as the asset’s warranty or service contract information, manuals, photos or special handling instructions. You can have all the information at your fingertips in the WO without having to reference the asset record. If this work order is from a service request, then any attachment made to the service request record will be carried over and shown on this screen.

Click Browse… to locate and select the file you would like to attach and then click the Upload button. When the upload is complete, the File Description field will be auto-filled. Upon successful upload, a new blank field appears, allowing you to attach another file. Be sure to click Save after any modifications.

To view the file, click Preview and the attachment will open in a new window.

Work Order Manager - Procedures Tab

In the Procedures screen, assign a procedure to the work order. However, you cannot edit original procedure records in this screen. To modify an original procedure record, navigate to Data Administration -> Procedures. Click View Procedure to display the full procedure text (read-only). Whether the text opens in a new window or a new browser tab depends on your browser.

To view any files previously attached to the procedure or to attach a new file, such as an image, click Attachments. If any files were attached to the procedure when the procedure was originally entered (Data Administration -> Procedures), those files will be listed here in the Attachments window.

To add a new attachment, click the Browse… button to locate and select the file. Click Upload to upload the file to the database and the Description field will auto-fill. To view the attachment in a separate window, click Preview. Adding an attachment to a procedure in this window will add the attachment globally to the procedure, not just for the work order record you’re currently modifying. Click Save to save the attachment and close the window.

Click Save to save the procedure record. To enter an additional procedure record, click the New button and use the Procedure ID pop-up list to select another procedure. The record navigation bar (to the left of the New button) shows the number of procedure records attached to the work order.

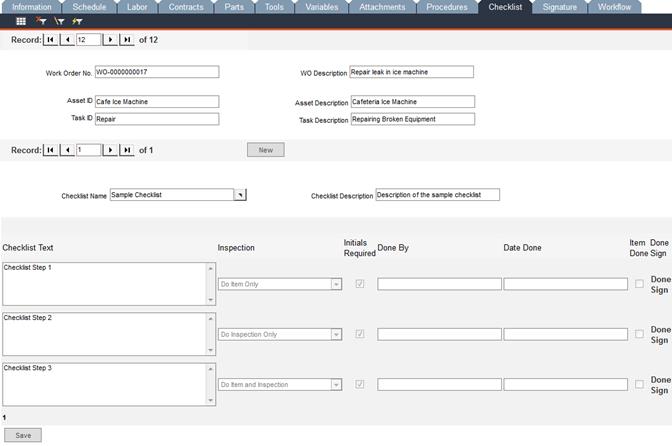

Work Order Manager - Checklist Tab

The checklist associated to the task selected will populate this tab.

When entering the original checklist record, you specify whether or not initials are required for each step. This specification translates to the Checklist tab in Work Order Manager: if the original checklist record shows that initials are required for a particular step, the Work Order Manager -> Checklist tab will show Done Sign in the row associated with that step.

If there is no checklist associated with the original task, but this work order requires a checklist, use the Checklist Name pop-up list to select a checklist; the fields below will auto-fill with information entered within Data Administration -> Checklists.

When a checklist item has been done, click Done Sign and the Log In form will open. Enter your User ID and Password and click OK. Only the user currently logged in can sign. This action checks the Item Done checkbox and attaches your electronic signature to the checklist item. When an inspection is required (i.e., the Inspection field shows Do Inspection Only or Do Item and Inspection), click Inspected Sign and the Log In form will open. Enter your User ID and Password and click OK. This action checks the Inspection Done checkbox and attaches your electronic signature to the checklist item inspection. If a checklist item does not require a signature, simply check the Item Done or Inspection Done checkboxes as appropriate.

To enter an additional checklist record in this window, click the New button and select another checklist record.

Only after each item in the checklist has been completed and marked as done will you be able to complete the work order by checking the Completed checkbox in the Information tab of Work Order Manager. Save the record. If the electronic signature feature is enabled, FaciliWorks will prompt you to sign the record.

To attach your electronic signature to the work order, access the Signature tab. Click the Sign button in the Done By pane; the Log In form will open. Enter your User ID and Password and click OK. Only the current user logged in can sign the work order. This action attaches your electronic signature and the button previously labeled as Sign is now labeled as Unsign.

Use the same steps to attach an electronic signature in the Approved By pane.

If the work order needs to be modified and has been signed, it must first be unsigned (can only be unsigned by the original signer). If a signature has been attached to the approval, the Approved By record must be unsigned before the Done By record can be unsigned (the Unsign button in the Done By pane will be inactive until the approval has been unsigned).

To unsign a record, click Unsign. The Sign In form will open. Enter your User ID and Password and click OK. A Comments box opens, giving you the opportunity to enter any necessary notes. If you enter notes here, click Save to save the notes and complete the unsigning. If you do not want to enter any notes, click Cancel to close the Comments box and complete the unsigning.

FaciliWorks will show the electronic signature details of each signing and unsigning of the record.

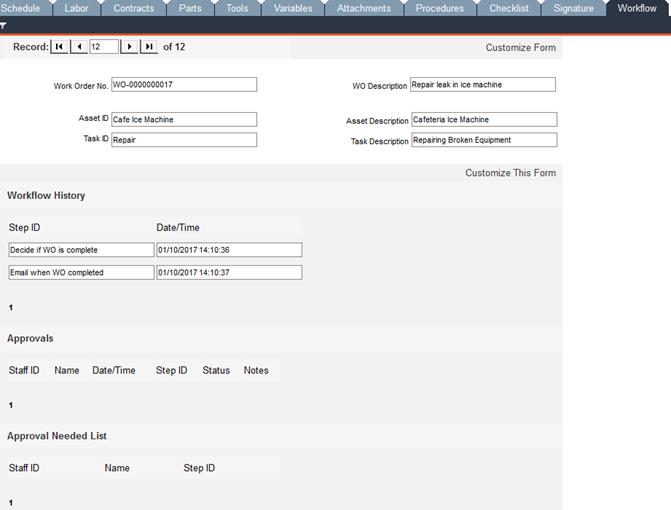

Work Order Manager - Workflow Tab

While the actual steps and triggers are defined in Workflow Trigger Setup and Workflow Step Setup, this tab shows the history of the actions and approvals involving the work order. For more information about workflow, please see the FaciliWorks Administrator Guide.

The Workflow History pane details all the steps executed after a particular workflow is triggered. Keep in mind that a workflow is triggered when a record is created, deleted, changed or verified.

The Approvals pane displays the history of approvals for a particular job. It also lists items set as Approved or Not Approved.

When a job is approved, it is removed from the Approval Needed list and moved to the Approvals pane.

Through Multitask Work Orders, FaciliWorks 8i allows you to create a single work order for multiple assets as well as assign multiple tasks to each asset. The forms in this module, except for the two discussed below, are similar to those within Work Order Manager. Enter this information as described in the Work Order Manager section.

Multitask Work Orders - Asset List Tab

In this screen, attach multiple assets to a single work order. Each asset can have multiple tasks. The upper row of tabs here, with the exception of the two explained below, are similar to those found within a typical work order. Please see the Work Order Manager section for details. The sub-tabs within the Asset List tab are identical to those of a typical work order and can be filled out as such, but they apply only to the specified asset.

Enter all information for the first asset, then return to the Asset List -> Information sub-tab and click the New button to enter the second asset. FaciliWorks will display a message asking if you would like to copy all of the sub-tab information from the first asset to the second asset. Click Yes to copy the information to the second asset or click No to enter all sub-tab information manually.

Asset List - Task List Sub-tab

Navigate to the Asset List -> Task List sub-tab and use the Task List sub-tabs to assign multiple tasks to a single asset within the Asset List. Use the Task List -> Information sub-tab to select a task and use the remaining tabs to enter the other task-related information as previously.

Asset List - Task Order Sub-tab

Use this tab to dictate the order in which the tasks are to be performed on the asset. To change the sort order of the assets in the list, use the Move Up and Move Down buttons. If the work on a particular asset must be completed prior to the work on another asset, note this by clicking the Requires Prior Completion checkbox.

The fields related to workflow (scroll to the right to see the fields) are used only if workflow steps and triggers have been defined within Configuration -> Workflow Step Setup and Configuration -> Workflow Trigger Setup.

Check the Notify When Complete checkbox to automatically send an email notification to a list of recipients.

Please see the FaciliWorks Administrator Guide for more information about workflow and email notification.

Multitask Work Orders - Asset Order Tab

To change the sort order of the assets in the list, use the Move Up and Move Down buttons. If the work on a particular asset must be completed prior to the work on another asset, note this by clicking the Requires Prior Completion checkbox.

The fields related to workflow are used only if workflow steps and triggers have been defined within Configuration -> Workflow Step Setup and Configuration -> Workflow Trigger Setup.

Check the Notify When Complete checkbox to automatically send an email notification to a list of recipients.

Please see the FaciliWorks Administrator Guide for more information about workflow and email notification.

Completing a Multitask Work Order

Once the work has been performed, return to the multitask work order record and complete the remaining sections of the record:

Shutdowns Performed

Budgeting

Maintenance Done Date

Downtime

Actual Labor Hours

Actual Part Quantities

Variable Readings

Resolution Date

Since multiple checklists can be used throughout this process, be sure to sign any checklist items that require signatures.

After entering the remaining information, each task can be separately marked as complete (within the Task List -> Information sub-tab). Then, each asset can then be separately marked as complete (within the Asset List -> Information sub-tab). Then, the work order can be marked as complete.

Without completing assets and tasks individually, the work order in its entirety can be marked as complete which in turn marks all assets and tasks as complete. The work order is marked as complete within the Multitask Work Orders -> Information tab. Check the Completed checkbox. You’ll be prompted with a message detailing the assets and tasks that are still open; click Yes to continue to complete the multitask work order. You’ll also be prompted for a maintenance done date if you hadn’t previously entered it.

Be sure to click the Save button at the bottom of the Multitask Work Orders -> Information tab before exiting the form.

Navigate to Work Orders -> Maintenance Jobs Status to view a chart of work order, PM and service request information, including total counts open and closed of each and total labor hours, labor cost and contract cost. This form is not editable.